Solution

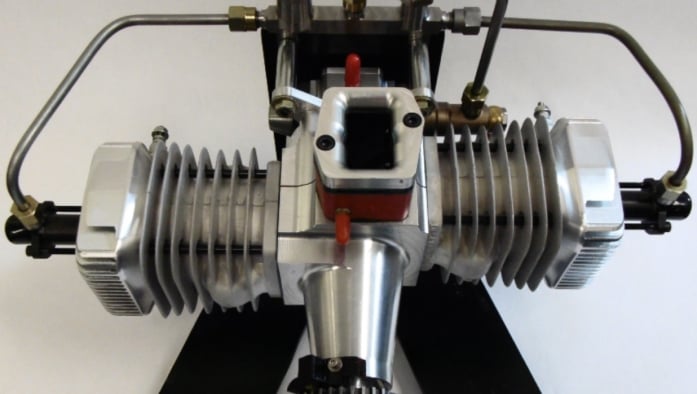

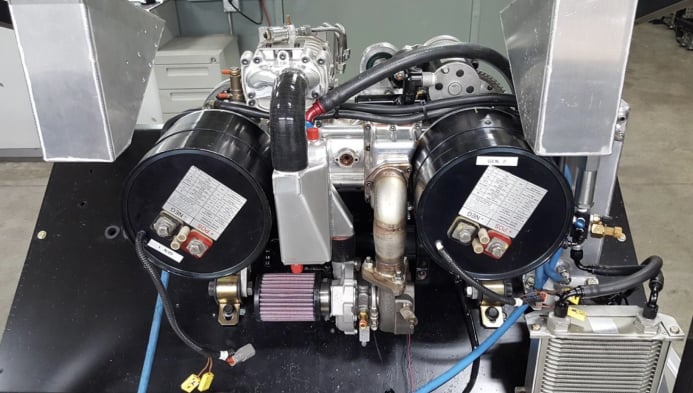

Baker Engineering approached the need for small scale fuel system components for compression ignition heavy fuel engines from multiple directions over the course of several consecutive SBIR efforts for diverse DoD customers including US Navy, US Airforce and US Army, ultimately developing a compact common rail fuel system and demonstrating the system on several engines from 28 cc to 400 cc per combustion chamber.

The Micro CI fuel system consists of the Micro CI injector, the Micro CI pump, a passively regulated common fuel rail, and an engine integrated pump drive.

The Micro CI injector is a solenoid actuated common rail diesel injector with reduced body length, flow optimized for engines of 2-35 hp per combustion chamber, and application specific needle travel and spray geometry.

The Micro CI pump, currently available in two capacities can be operated up to 1000 bar fuel pressure and up to 7500 cycles/min depending on application requirements. In most small engine applications, the Micro CI pump is paired with a single injector.

Fuel pressure in the Micro CI fuel system is passively controlled by a bypass fuel pressure regulator integrated into the compact common fuel rail. Active control can also be achieved through metering of the pump inlet by inlet pressure or by an inlet metering valve depending on desired system complexity and weight requirements.

Baker Engineering continues to improve the system, most recently developing internal capabilities for measurement of injector flow to create injector calibration data sets for use in engine calibration.

- Micro high pressure fuel pump and drive

- Compact passively regulated fuel rail

- Compact solenoid actuated common rail injectors

- Engine integrated pump drive