Solution

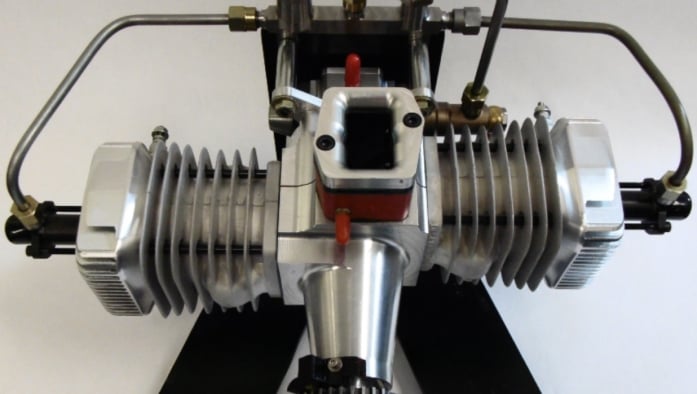

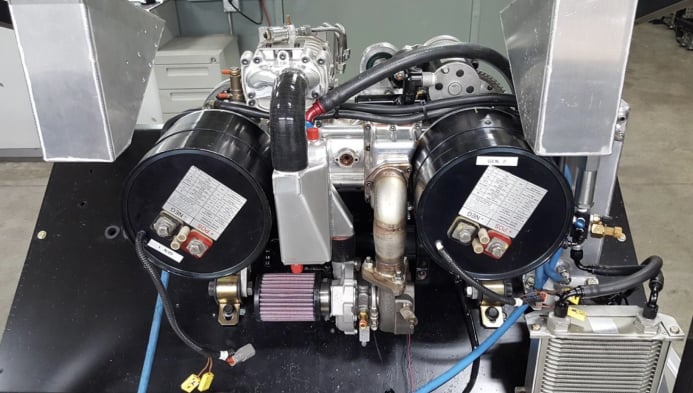

Baker Engineering has specialized knowledge in the design and manufacture of lubrication systems including gerotor style oil pumps. To support the addition of an oil lubricated turbocharger and fuel pump drive on the Baker Heavy Fuel Rotary Engine, a compact, lightweight dry sump oil system was developed. The core of this system is a bespoke 3-stage oil pump featuring an integrated pressure regulator, oil filter, pressure sensor, and temperature sensor.

The pump design features a single pressure stage supplying pressurized oil to an oil journal bearing turbocharger and a roller bearing supported pump drive assembly. The turbocharger and pump drive both have a scavenge pump section to evacuate oil and return it back to an external dry sump tank.

Prior to pump design, testing was completed on prototype hardware to evaluate required oil flow for both cooling and lubrication. Gerotor geometry was scaled based on proven designs from past Baker Engineering projects with additional optimization to inlet and outlet geometry to improve volumetric efficiency. An internal bypass regulator controls output pressure, and an integrated oil filter mount enables easy maintenance and helps keep system weight down.

The final result is a compact oil pump design weighing only 2.7 lb with oil filter, sensor, fittings, and drive pulley installed. Future development of this system may include further integration of the pump hardware into the main engine housing to reduce part count and minimize external oil lines. Baker Engineering has utilized similar gerotor style oil pumps for many small engines including 2-stroke and 4-stroke applications and can lean on a library of past performance knowledge to develop new designs with confidence.